Pipline Inline Inspection & Assessment

Inline Inspection

Modern intelligent pigs are highly sophisticated instruments that vary in technology and complexity by the intended use and by manufacturer. An intelligent pig, or smart pig, is basically a computer that collects various forms of data during the trip through the pipeline. The smart pigs are divided into the following types:

Caliper: The Caliper Tool gathers geometrical data from the pipeline and it is necessary to run the Caliper before using other intelligent pigs.

MFL: The MFL Tool measures the amount of leakage of a magnetic flux which is generated as a loop that passes the pipe wall thickness to find internal and external metal loss features.

UT: The Ultrasonic Pig uses special transducers to generate a special signal. The signal passes through the pipe wall thickness and therefore the transducer gets several echoes. By measuring the intensity and energy of the received signals, it will find and estimation of the pipe wall thickness in every region near the transducers. By analyzing the data from UT Pig Run, we can find the exact location of each metal loss feature and also we can get an estimate of its size.

ILI Tool Running

In case inline inspection is required for a pipeline that is out-of-service or an inspection tool needs to be run with a medium different from the pipeline product like when a gas pipeline is needed to be inspected by UT tool and the tool is required to be run inside a water batch or fully flooded pipeline.

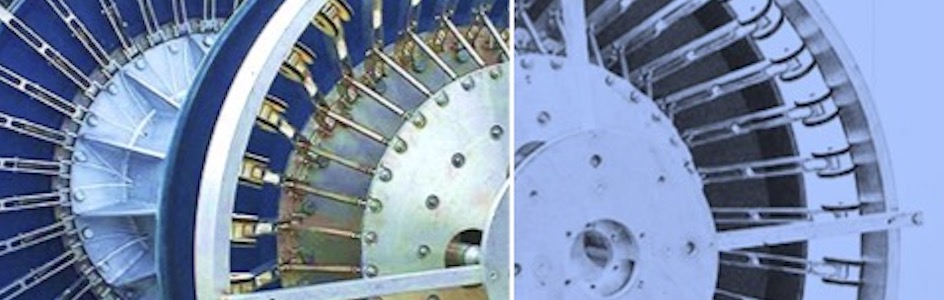

IPEC provides ILI tool running services for various pipeline sizes and different ILI tools. Working hand in hand with ILI technology providers gives them the freedom to focus on the inspection tool and data analysis. Based on the technology of the tool and the condition of the pipeline, required flow rate and pressure is defined and these requirements are provided by means of IPEC’s fleet of pump stations. These pumps are suitable to run various inspection tools such as Caliper Tool, MFL, TFI and ULTRASONIC.

We do understand the challenges of running an ILI tool with steady speed. That’s why we always provide highly reliable pumping facility with spare equipment when participating in such projects. Based on our experience in both onshore and offshore fields, IPEC can be a suitable partner for technology owners in their inspection projects.

Defect Assessment and FFP/FFS

We provide Fitness for Service or Fitness for Purpose assessments which is the activity that is performed to decide whether a pipeline can continue to be used for its intended purpose at specified working conditions. FFS is a key activity in the ageing management of pipeline that is subjected to a degradation mechanism, such as corrosion. FFS supports the management of ageing pipeline by predicting the possible damage sites and modes of failure, estimating remaining life and justifying the extension of life beyond the design life. FFS can be performed once the results of ILI have been obtained to provide charts for assessing the results as they are obtained.

Pipeline Integrity Management System (PIMS)

Operators of pipelines in the oil and gas and other high-hazard industries must be sure that equipment and materials are fit for service and functioning according to the highest safety and production levels in order to stay compliant and profitable. Pipeline integrity management (PIM) is a system used by pipeline owners and operators to ensure a pipeline's safety from its conception to its retirement. Pipeline integrity management is used to address many aspects including health, safety, and environment (HSE), engineering, inspection, maintenance and other branches of pipeline labor. PIM programs consider all stages of the pipeline life cycle, from conception, to engineering and design, construction, operation, inspection, and finally to repair/replacement when necessary.

Tank Wall/Floor Inspection

Plant owners and operators must be certain that dangerous defects and damaging corrosion in tanks are detected and monitored to facilitate maintenance strategies and meet safety standards. Non-destructive inspection services are part of a reliable maintenance program for tanks to prevent and control corrosion damage that could potentially halt production or pollute the environment. Our non-destructive tank inspection services provide you vital data needed to determine the actual condition of your critical equipment enabling you to monitor and control any production or safety issues that may arise. Our expert inspectors conduct inspection to reliably detect and watch damaging corrosion in thick-walled storage tanks.